Open Die Forging: A Manufacturing Philosophy Engineered for Performance

Open Die Forging is a process that shapes metal between flat or contoured dies under compressive force. Its core value lies in optimizing the metal's internal grain structure through immense pressure, creating a continuous grain flow that follows the part's contours. This results in superior toughness, fatigue strength, and overall mechanical properties compared to cast or welded alternatives. For core components enduring complex loads, impact, and harsh environments, Open Die Forging is the definitive choice for ensuring long-term reliability.

Liaoyuan's Open Die Forging Advantages: Full Process Control, Superior Quality

-

Materials Science & Custom Selection

We partner with top-tier steel mills to select the most suitable alloy steels, carbon steels, or special grades based on your component's operating conditions (e.g., strength, toughness, corrosion resistance requirements), laying the foundation for exceptional performance.

-

Precision Heating & Forging

Billets are uniformly heated to precise forging temperatures in our computer-controlled industrial furnaces. Our experienced forgemasters then use large hydraulic presses to accurately shape the preform through processes like drawing out, upsetting, and piercing. The primary goal of this stage is to thoroughly break down the as-cast structure, eliminate potential defects, and achieve a dense, homogeneous forged microstructure.

-

Performance-Enhancing Heat Treatment Systems

After forging, components undergo a strictly controlled heat treatment process (e.g. quenching and tempering) to develop the ideal microstructure, imparting the required combination of mechanical properties, including strength, hardness, toughness, and wear resistance.

-

As your one-stop manufacturing partner, we provide a full-range machining service from rough forging to finished part. In our machining workshops, forgings undergo both rough and finish machining to achieve the precise dimensions and surface finishes specified in the drawings, ensuring perfect delivery and readiness for assembly.

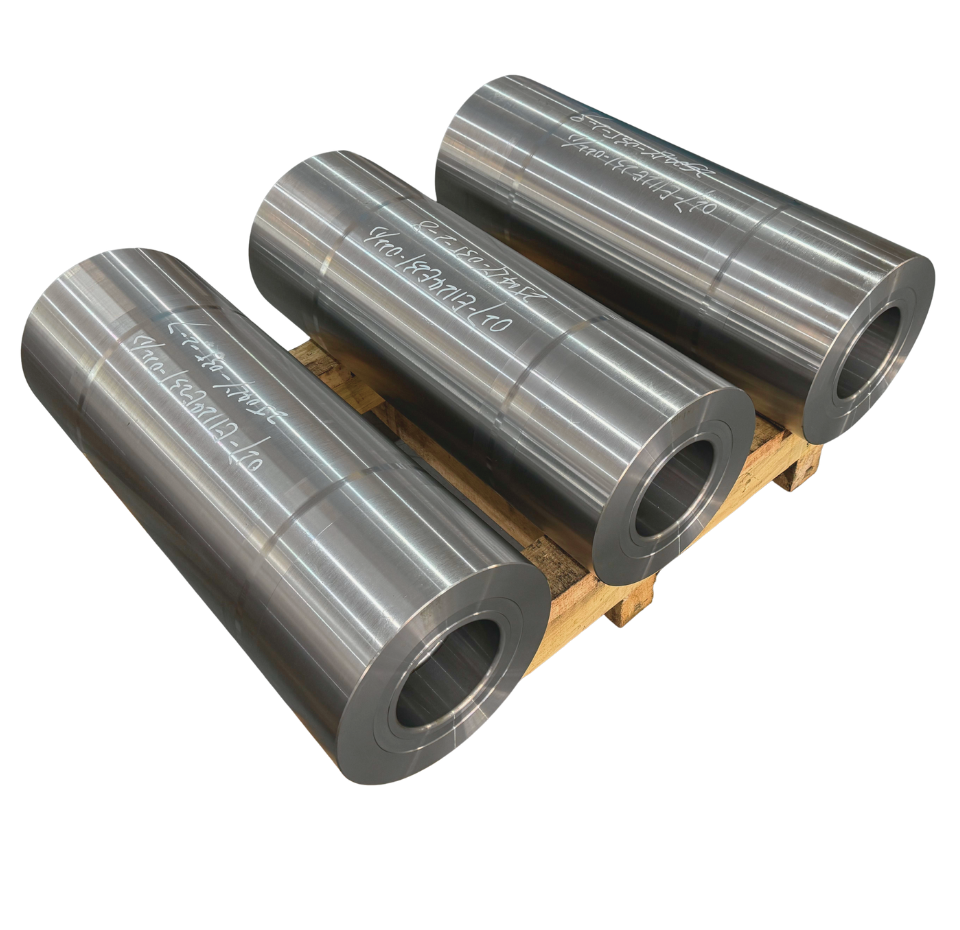

Our Representative Open Die Forged Products (Finished Weight: 100kg - 6t)

- High-Strength Shaft Components: Such as generator rotor shafts, large industrial pump shafts, intermediate shafts, and motor shafts for onshore wind turbines.

- Critical Cylindrical / Block Components: Such as heavy-duty hydraulic cylinder barrels, mill rolls, equipment base blocks, and customized tooling blocks.

- Custom-Shaped Preforms: We forge blank parts of various non-standard geometries according to your unique designs, providing high-quality preforms for subsequent machining.

Why Choose Liaoyuan as Your Open Die Forging Partner?

- Precise Capacity Focus: We specialize in medium to large open die forgings within the 100 kg to 6-ton finished weight range, delivering optimal cost-effectiveness and quality assurance within this scope.

- Integrated Forging & Machining: We provide a true turnkey solution, controlling the entire process from raw material to finished machined part under one roof, ensuring quality, saving time, and reducing your total cost of ownership.

- Profound Technical Expertise: We possess a deep understanding of various industrial application requirements and provide end-to-end technical solutions from material selection to heat treatment.

- Comprehensive Quality Assurance: Our processes are certified under ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 systems.

- Flexible Response to Market Demands: Our flexible production scheduling system efficiently handles both batch orders and custom projects.

Explore Our Specific Products or Inquire About Your Custom Project: